Article by Gary Minke

History – October 2005 – Colorado Central Magazine

NINETEENTH-CENTURY MINING in Park County naturally kindles thoughts of gold and silver (and of the hard rock tunnels along Buckskin Gulch, and the big hydraulic washing operations which churned the riverbanks near Fairplay and Alma). But coal was also an important product during the exciting years of gold and silver extraction (1867-1893). Unlike Appalachian operations, however, the coal industry in South Park employed only a single generation of miners.

Most of the men who worked in the South Park coal fields came from half a world away — Italians, Austrians, Chinese, and Swedes. And approximately 70 of them took their final dusty breath under the slope mines at King (one of the many towns in Colorado that would simply disappear from the map).

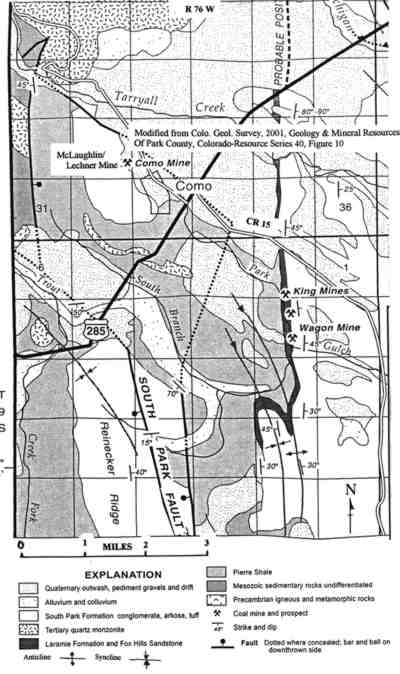

Dan McLaughlin started digging coal in 1867 from steeply inclined rock layers (Laramie Formation sedimentary rocks approximately 65 million years old) on his ranch near what would later become the town of Como.* McLaughlin sold coal by the wagonload to mines and ranches around Fairplay.

But by 1872, George Lechner, an entrepreneur with more political and financial backing, bought the old Stubbs and McLaughlin ranch holdings and started developing the coal deposits. Lechner expanded the McLaughlin mine and located additional veins in the same Laramie Formation along Park Gulch about three miles to the east.

Until the Denver South Park and Pacific Railroad reached Jefferson and Como in 1879, coal extraction was a small operation producing just enough for local consumption. But over the next few years Lechner’s South Park Coal Company was sold to the DSP&P and finally to the Union Pacific Coal Company. Then there were train loads of coal being shipped to Denver, and to local mines and smelters, and local coal was also used to operate the steam locomotives themselves.

That coal mainly came from the six mines along Park Gulch referred to as the King Mines named for A.J. King, the county clerk of Fairplay who ran the general store and post office at King. Mine openings 5, 1, 3, 4, 2 and 6 stretched out for approximately a half-mile from north to south at King.

As depicted in Mary Dyer’s publication, Echoes of Como (1974), the settlement at King had 60 to 70 frame houses, two saloons, a post office, a company store, a schoolhouse/church, and coal offices. A narrow-gauge railroad spur carried the coal from King to Como.

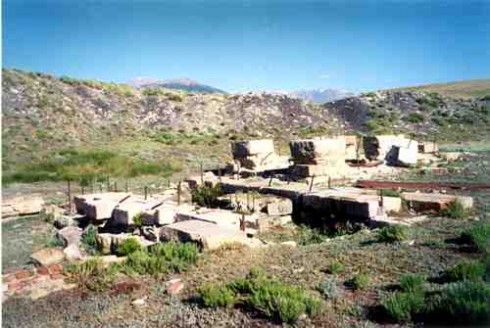

Mining operations were difficult because of the geometry of the coal veins which dipped or were inclined eastward at a 45-degree angle. The coal workings developed on this slope were referred to as slope mines. Steam engines were installed to run air compressors for ventilation and to run cable drum winches that operated elevators or pulled loaded coal cars on rails up the slope to the mine entrances.

A series of small rooms or shoots were blasted and dug into the coal seams and connected by cross cuts developed on eight different levels stacked about 125 feet below each other. Since the mines were along the Park Gulch drainage, large amounts of water had to be pumped from the workings. There were three coal seams. The main or lower seam was about 8 feet thick and the two thinner seams (1.5 to 4 feet thick) were 187 and 220 feet above the main coal. Coal mining never extended below 2000 feet in the King slope mines.

When business was booming there were about 350 miners employed in the coal mines at King. Nearly a third of them were Chinese working through a contract with Edward L. Thayer, a labor manager. The Chinese likely lived near the Hamilton gold placer above Como. Most of the remaining miners, who were predominantly Italian, resided at King.

Some of the miners had wives and children living with them so the company town needed a schoolteacher. The full-time teacher in 1888 was a Mrs. Kesner. In 1892 there were 71 pupils attending classes at the school in King. A few miners and most of the American supervisors probably lived in Como.

The average miner made $2.50 per day, and in 1885 the miners formed a Knights of Labor organization with 300 members. The work was hazardous and fatal accidents were not uncommon. Fully loaded coal cars were winched up to the mine entrance, with men standing on the couplings between them in order to help with the unloading process. And occasionally a coupling broke — with disastrous results.

The Fairplay Flume of January 1, 1885 reported one such accident. “Mr. A.J. King reported a fatal accident in which two Italian miners were killed last Friday. Mike and Cosmo Dominico were riding on a train of 4 loaded coal cars being drawn from the 6th level to the top of the shaft in the #1 Mine (at King). When up about 60 feet the coupling back of the first car broke letting the three cars and two men drop back on an angle of nearly sixty degrees with frightful velocity. The cars and men went through a heavy iron door on the sixth level about 175 feet below. Mike (25 years old) was killed instantly. Cosmo (19-year old brother of Mike) was taken home but died three hours later. Both men had worked in the coal mines for about three years.”

A month later the same kind of accident at the #1 Mine killed Scott Purdy (a pumper from Illinois). The coupling break happened between the 7th and 6th levels.

That same year, an explosion in the #1 Mine (probably involving a combination of methane gas and coal dust which ignited during a blasting operation) claimed the lives of 35 Chinese miners. A cave-in resulting from that explosion made it impossible to recover the bodies of the men.

The natural faulting and fracturing at the south end of the #5 Mine (in the lower seam) carries through to the #1 Mine (developed in the upper two coals) possibly making this area more susceptible to cave-ins. An accident that hastened the end of mining at King happened on January 10, 1893. At 25 minutes before noon, twenty-five men were working in the Number 35 shoot on the sixth level (south side) of the #5 Mine, and an explosion killed all of them.

The coroner’s inquest placed the blame on Stephen Conti who had loaded drill holes and set off the blast which spread like lightening out into the cross cut where the men were waiting to shovel the freed-up coal. Several witnesses swore there was no methane gas present, but there was some coal dust, which apparently ignited.

Other bosses and the mine inspector testified that Mr. Conti had loaded drill holes that were too close together (12 to 18 inches apart), so instead of the blasts occurring sequentially, they reinforced each other to produce a simultaneous killing shot.

The dead included 15 Italians, 6 Austrians, 1 Swede, and 2 Americans. Only three of the dead miners left grieving families at King: Robert Blythe, the fire boss, left a wife there; Stephen Conti had a wife and four children; and Charles Antonelli left a wife and two children. But many of the other miners were married men who had not brought their wives and families to America.

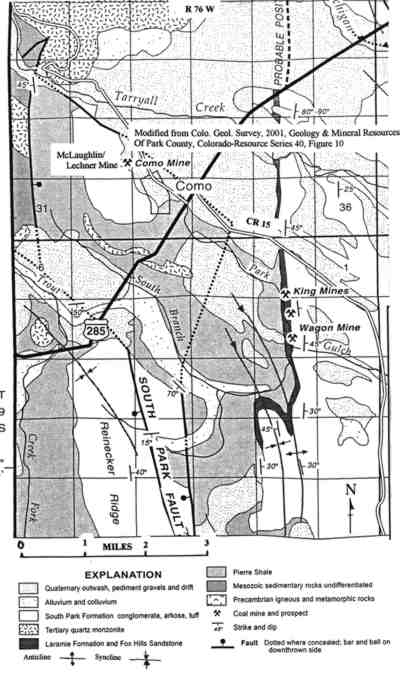

The coal mines at King were often referred to as the “lower coal banks of Como.” The location of Section 2, T. 9 S., R. 76 W. clearly places the mine at King and not Como where only one mine was constructed. There were at least 6 mines at King. This old Department of Natural Resources map depicts the workings of the #5 Mine as it was being worked in 1885. North is indicated. The scale is difficult to read but approximately 3/8 inch equals 100 feet on this reduced copy. Just north of the word Como are the rectangles indicating the steam engine mountings at the head of the #5 Mine. Photographs on the previous page show what is left of those mountings. The spindle-shaped loop at the mine head shows the railroad branch where the coal cars were 1oaded. There are eight separate levels of mine workings. Since the coal seams are inclined 45 degrees to the east, each level stairsteps downward. Level 1 is just below the surface at Park Gulch whereas Level 8 is approximately 1,100 feet below the ground surface.

IT IS DIFFICULT TO SAY how much coal was taken out over the 18 best years of production (1875-1893) at King. The Fairplay Flume of September 11, 1879 reported the Como coal mines production capacity at 100 tons per day. In 1885 the King #1 Mine produced 58,997 tons or an average of 162 tons per day. The #5 and #6 slope mines at King yielded about 150 tons per day during peak output. In mid January of 1885, the total production from the King Mines reached 800 tons per day.

The Colorado Geological Survey in its Colorado Resource Series 40 of 2001 reports an estimated 135 million tons of coal remaining in the South Park Coal Field but only 35 million tons are within 1000 feet of the ground surface. The coal seams are steeply dipping, vary rapidly in thickness, and are complicated by faulting. So it is unlikely that these mines will ever again become as important as they were in the 19th century.

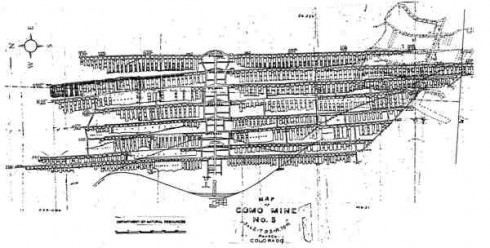

By 1900, King was abandoned, and many of its houses had been moved to Como and nearby areas. The rest of the buildings were torn down for scrap material. Today, when you gaze across the lonely landscape, you can barely tell that King ever existed.

Except for some foundation remnants and the weed-covered spoil mounds at the head of each collapsed mine entrance, nothing remains. There are no buildings – or grave markers to indicate the location of the town cemetery. But the ghosts are still there, and the ground carefully holds their secrets — forever.

Gary Minke is a resident of South Park and one of the directors of the Park County Historical Society.